STORAGE STRUCTURES

To cope with the current and future demand of the increasing population for the food grains, it is emphasized to reduce the loss of seeds during and after harvest. seeds are stored for varying periods to ensure proper and balanced public distribution through out the year. Post harvest losses in India are estimated to be around 10 per cent, of which the losses during storage alone are estimated to be 6.58 per cent. But, with the advent of improved agricultural technology, the producer can afford to store the seeds for longer period with minimum loss.

For best storage performance,

1. The produce must be thoroughly cleaned and graded,

2. Dried to the safe storage moisture level of 10-12 % for cereals and 7-9% for oil seeds (on wet basis) for a safe storage period of 6-12 months.

3. Storage structures should to be properly repaired, cleaned and disinfected,

4. Structures should bear the load of seeds stored and do not permit contact/

exchange with outside humid air,

5. Structures should be constructed in the coolest part of the house/ farm.

An ideal storage facility should satisfy the following requirements

1. It should provide maximum possible protection from ground moisture, rain, insect

pests, moulds, rodents, birds, fore etc.,

2. It should provide the necessary facility for inspection, disinfection, loading, unloading,

cleaning and reconditioning.

3. It should protect grain from excessive moisture and temperature favourable to both

insect and mould development,

4. It should be economical and suitable for a particular situation

| Seeds can be stored in bulk or in bags. |

(a) Bulk (open) storage

It is preferred over bag storage for the following reasons

- Large quantities of food grain can be stored

- No difficulty in loading and unloading of grain

- No need to purchase storage containers like gunnies

- Insect incidence is less than bag storage, even this can be eliminated by fumigation in situ

- Avoids waste from leaking bags

- Easy inspections- saves labour and time.

|

|

Bulk seed storage

| (b) Bag storage |

- Commodities are mostly stored in gunnies. Storage in bags requires considerable labour, but the minimum investment is enough on permanent structures and equipment. The storage in ags has the advantage of being short-term storage.

- Bag storage can be done under a roof alvanized iron sheets, a plastic covering where grain is intended for very early onward movement. Bags can be easily handled for marketing purpose.

- There is no sweating of bags as they are arranged in racks with proper interbag space, but, initial cost is high and they can easily pickup infestation and retain even after treatment.

|

|

Storage structures used by the farmers are

CONVENTIONAL STORAGE STRUCTURES

Structures |

Make |

Stored

items |

Capacity |

Remarks |

1. Bamboo

structures |

Split bamboo woven in the form of a cylinder with wide base and narrow mouth |

Paddy,

wheat and

sorghum |

500 kg |

Life 4-5 years.

Weight loss due to insect attack is 5 % in paddy and 15 % in sorghum. |

2. Mud and

earthen

structures |

Clay, straw and cow dung- 3:3:1. Earthen structures are made, sun dried and then

burnt in fire |

Paddy, wheat,

sorghum,oil seeds

and pulses |

5 to 10 q |

Life 8- 10 years.

During rainy season develop cracks and moisture absorption

followed by insect and mould

infestation. |

3. Wooden

structures |

Local wood is painted black. At the top, 30 cm x 20 cm in let and

at the bottom 30 cm x15cm outlet is provided |

Paddy |

10 q |

15- 20 years. Neither airtight nor moisture

proof. |

4. Brick

structures |

Rectangular,

structures built as part of the house, with brick in cement or lime mortar having a

wall thickness of 40 –50 cm. At the top 50x 50 cm inlet and at bottom 15 x15cm

outlet is provided. |

Paddy,

sorghum

and wheat |

25- 30 q |

25- 30 years. High initial cost, not insect and moisture proof. |

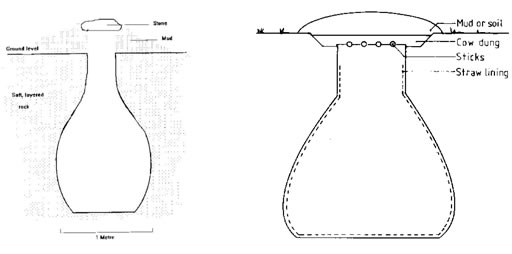

5.Underground

structures |

Circular pits vary

from 100– 400cm in depth and 50 – 100 cm dia at neck and 250 – 300 cm at the bottom. For filling and emptying there is

an opening at the top. Before filling the sides and bottom are packed with straw

and husk. After filling the pit is gain covered

with straw and stone, the finally with mud. |

Cereals |

100 –200 q |

Safe against insects but, loss of seed viability and handling

difficulties made it out of date. |

6.Miscellaneous

plant materials

a. Paddy straw

b. Stem of vitex

and pigeon pea

stalks

c. Bottle gourd

shells |

a. paddy straw is

wound in the form of rope to varying diameter

b. stems wound like a bin and both sides are

plastered with mud and cow dung

c. empty shells are used |

Paddy,

other

cereals

and pulses Paddy and

other

cerealsPulses, gourd

seeds |

30–100q1-2 q2-5 kg |

Not insect and rat

proofTemporaryOnly small quantity of seed lots. |

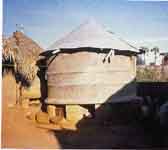

7. Metal

corrugated G.I.

sheets |

Sheets of about 3 m high are held

vertically along one edge and edges of the

other sheets are

overlapped and bolted to each other. Thus

the circle with 2-4 m dia. is completed with

many such sheets. They are covered on

the top with the plain M.S. or G.I. sheets. |

Various

types of

seeds |

Vary |

Vary Temporary |

8. Hessian cloth

bags |

|

|

|

|

| 9. Gunny bags |

|

|

|

|

IMPROVED RURAL - LEVEL STORAGE STRUCTURES

1. Bitumen/ coal tar drum

An alternate model of metal bin, low cost with similar technical performance. These bins are of 520 mm dia and 900 mm height. They can store 1.5 q of wheat and 1.2 q of Bengal gram.

2. Hapur bin/ Kothis

Circular bins of 2, 5, 7.2 and 10 q capacities and have potential to meet requirements of even large farmers.

3. Udaipur bin

These bins are made out of used coaltar drums. These can stock 1.3 q of wheat and maize. These bins can be made to have more airtight lid if the drum outlet end is given small cut to unload the bitumen. These bins are suitable for storing of food grains for short duration and can be adopted by small farmers.

4. Stone bin

Stone bin (Chittore bin) is made of locally available 40 mm thick stone slabs with dimensions of 680 mm x 1200 mm with square cross-section. The inlet and outlet are made of asbestos. This bin has a capacity of 3.8 q.

5. Bamboo bin

These bins are made of two walls of bamboo with polythene lining in between and have varying capacities. These bins are suitable for short – duration storage and can be adopted by small and marginal farmers.

6. Baked clay bin

Baked clay bin of 7q capacity (paddy) is made of 16 burnt rings jointed by mud plaster; cement mortar and cowdung coatings one after another. The ends of the rings are made in such a manner that they fit into each other. These rings are kept on a polythene sheet covered and plastered platform of brick mansory and cement sand mortar. An outlet is provided for the discharge of the grain. The top is covered with a mild steel lid. Because of the low cost and good performance these are particularly useful for small and marginal farmers who do not store their produce for longer duration.

7. PKV bin

Made from green bamboo splits into suitable sizes. The tunnel, outlet flap valve and complete stand can be fabricated in a workshop.

8. Pusa bin

It is a modification of the ordinary mud storage structure commonly used in villages. To provide moisture proof and airtight conditions, polyethylene film of 700 gauge thickness has been embedded at the top, bottom and on all the sides of the mud bin. The embedding process provides mechanical support and safety to polyethylene film. The construction of outer walls with burnt bricks up to 45 cm height makes the structure rat proof as well. The bin is constructed with unburnt bricks on burnt bricks or concrete floor to avoid rat burrowing. The grain and seed both remain safe in the bin for more than one year with proper precautions.

9. Pusa Cubicle

This is a room like structure ( 3.95 x 3.15 x 2.60 m), a modification of Pusa bin to provide large storage capacity of 24 tonnes on a platform of 3.73 m x 2.93 m x 0.07 m is made with unburnt bricks on a concrete floor (except 22 cm of outer sides with burnt bricks). A polyethylene sheet is placed on this platform and another platform of similar dimension is made with unburnt bricks. The 22 cm thick inner walls are constructed upto 2.6 m height. A wooden frame of 1.89m x 1.06 m for door is fixed in the front side of 3.95 m wall. The roof can be made by wooden beam placed at 15 cm distance and covered with unburnt bricks.

10. Pusa Kothar

Presently storage is practiced in small compartments of a room (5.3 m x 2 m x 4 m) called kothar. The roof is constructed with the help of wooden poles and mud slabs, leaving near the front wall three filling holes each of 0.5 m x 0.5 m size. Two out lets of G.I. sheets of 15 cm dia. and 30 cm length are fitted at the floor wall on the front side.

11. Metal bins

Bins made of steel, Aluminium R.C.C are used for storage of grains outside the house. These bins are fire and moisture proof. The bins have long durability and produced on commercial scale. The capacity ranges from 1 to 10 tonnes. Silos are huge bins made with steel/ aluminium or concrete. Usually steel and aluminium bins are circular in shape. The capacity of silo ranges from 500 to 4000 tonnes. A silo has facilities for loading and unloading grains.

STACKING

Food grains have to be stored and preserved on scientific lines in godowns till they are issued to consumer. Te bags containing food grains cannot be just dumped inside the godown, for it will not facilitate proper storage. Proper stacking ensures free access to the stocks in all parts of the godown for inspection and helps in effective disinfestations work. Generally, three methods of stacking are being followed: 1. Simple, 2.Cross and 3. Block method.

Steps necessary for good storage practice in respect of all food grains

Stored product pests can be managed either behaviouraly (traps viz., probe traps, light traps, pitfall traps etc.,) or with several preventive and curative measures (both chemical and non-chemical methods). Once a facility is obtained, a number of steps are to be taken to ensure safe storage of grains. These steps comprise,

1. Before storage

- Checking for leakage of rain water and sufficiency of drainage facilities

- Cleanliness of the facility and environment

- Assessment of capacity of the facility

- Pesticidal treatment

- Security and firefighting arrangements and

- Repairs to available equipment

2. After receipt of seed

- Inspection for variety and soundness of quality

- Inspection carefully for infestation, it any, and when present, for type and extent

of infestation,

- Inspection whether grain has excess moisture, whether it had been heated up in

earlier storage and has any musty or rancid odour

- Any grain rendered wet or damaged to be segregated and salvaged with facilities

available and check the weight received

3. During storage

- Maintenance of cleanliness

- Ensuring aeration where necessary

- Checking for leakage after rains

- Inspection for insects, rats and mites at fortnightly intervals

- Watch for advancement in deterioration, if any,

- Pesticidal treatments necessarily based on observations

- Ensuring disposal where called for, and

- Arrangement for segregation, salvage and processing, wherever, damage owing

- to leakage of water and other causes might have taken place.

SEED PROTECTANTS

Chemicals that can be directly applied to grains are formulations of chemicals having residual toxic or repellent action or both. Those are applied directly to the grain to prevent damage by stored product pests. Eg., clay minerals (red earth, Kaolin) before 1950. Now their use is restricted only to seeds and grains meant for animal feed. These grain protectants can be applied in the form of spray/ dust on the uninfested grain.

Advantages over fumigants

- Used as a prophylactic treatment

- Can be effective when the grains are stored in loose containers where fumigation is not possible

- Less dangerous than fumigants

- Don’t affect germination adversely

- One application at harvest time is sufficient for one year

Example

1. Pyrethrum synergized with PBO: safest of the grain protectants available and approved for use. Available as powder 1 % PBO +0.8 % pyrethrum, 0.83 lb synergist+ 0.6 % pyrethrum also be applied in the form of spray 3-5 gallons/ 1000 bushel, 0.6 lb synergist+0.066 lb pyrethrum.

2. Premium grade Malathion: Foul smell is removed. Can be directly applied over the grain as 1 % D or as a spray 57 EC. Other chemicals include: Carbaryl, Dichlorvos, Fenitrothion, Lindane, Malathion, PBO, Pyrethroids (Deltamethrin, Fenvalerate).

Source: http://www.extension.umn.edu/distribution/cropsystems/M1080-FS.pdf . |